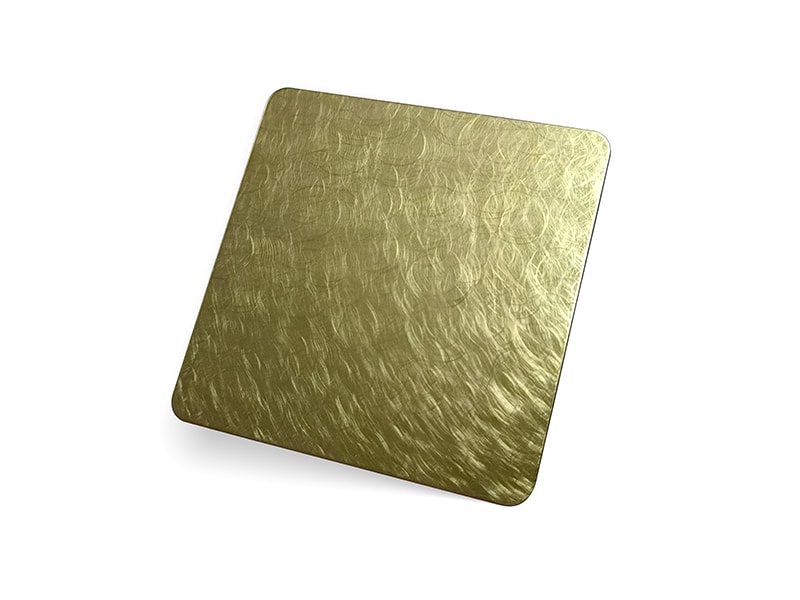

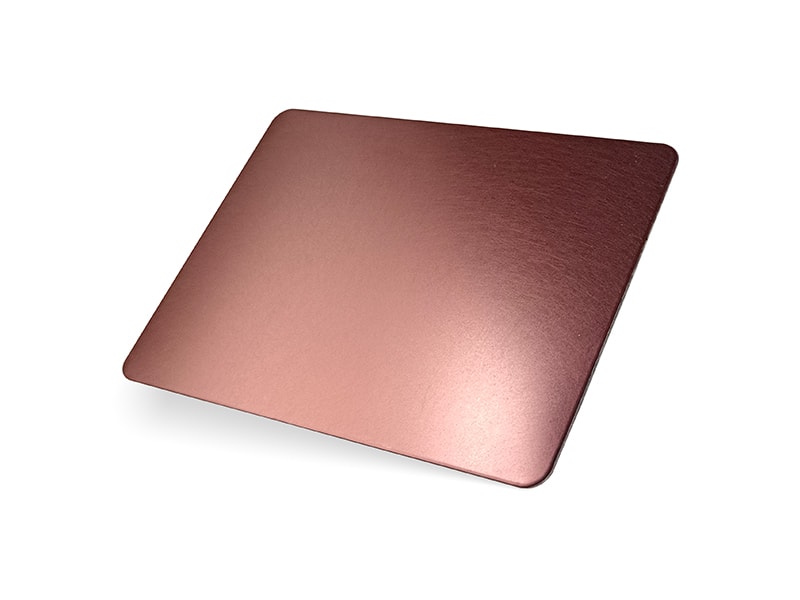

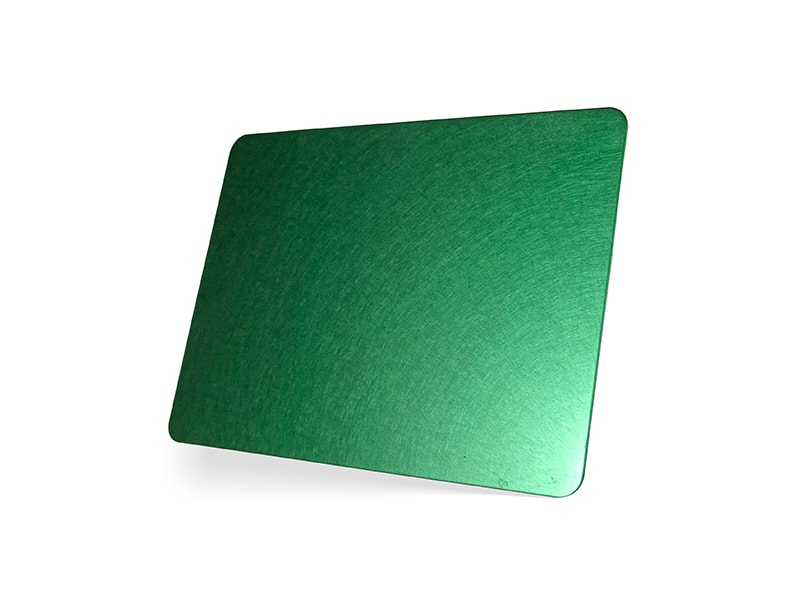

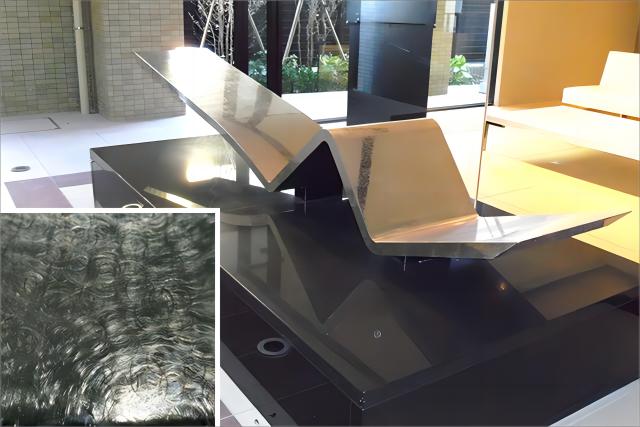

Vibration Finish

Q: Do you have a control sample finish production service?

A: Yes, we do. We promise a minimum 90% match to the sample’s finish standard, including pattern and colour.

Q: What's the Mill of Origin for your decorative stainless steel sheets?

A: TISCO, ZPSS, JISCO, Lisco, Baoxin, Hongwang, Yongjin, Aoxing, etc

Q: Can I get some samples?

A: We can provide stock decorative stainless steel sheet samples for you to check the quality. Stock sample is free and you just pay the freight. Also customized finish is avaiable and chargeable.

Q: Can you provide customized grades, dimensions?

A: Yes, we offer customization services for our stainless steel products based on your specific requirements, from thickness, width to grade. Just let us know your application.

Q: Which countries have you already exported?

A: We've exported to more than 31 countries, such as Canada, Russia, UAE, Iran, South Korea, Saudi Arabia, Vietnam etc.

Q: How long is your delivery time?

A: Trial orders can be delivered within a week. For regular orders, it takes 7-30 days roughly.

Q: How can you ensure the quality of your product?

A: All products are subject to three checks throughout the manufacturing process, including mill material processing, decorative finish productioning and packaging.

EN

EN