»

» - Product

Each of our finishes is not only visually appealing but also highly functional and durable, making them suitable for a wide range of applications such as ceilings, wall panels, backgrounds, hallways, and more.

Explore our range today and find the perfect finish to transform your designs. Explore Now

-

Water Ripple Finish

Introducing our exclusive range of Water Ripple Stainless Steel Sheets, designed to bring a captivating water ripple effect to your architectural and ornamental projects. Our sheets are not only visually appealing but also highly functional and durable, making them suitable for various applications such as ceilings, wall panels, backgrounds, hallways, and more.

Learn More -

Textured Finish

Textured stainless steel sheets are available in various patterns and designs, ranging from simple geometric shapes to more intricate motifs. The patterns can be raised or recessed, depending on the desired aesthetic effect. Common patterns include 5wl, 6wl, and honeycomb, among others. The texture is typically achieved by using a stamping process, where a pattern is pressed into the surface of the stainless steel sheet.

Learn More -

Etched Finish

X-Metal excels in crafting durable, precise etched patterns on stainless steel sheets via an electrochemical process. A resistant coating is applied to protect certain areas during etching, while unprotected areas undergo acid treatment, creating a dim, matte finish. Non-etched areas can be colored for contrast, forming captivating patterns tailored for specific effects. With its aesthetic appeal, this etched metal sheet is ideal for various decorative applications.

Learn More -

Antique Finish

The Antique Finish series offers brand new stainless steel sheet finishes that cater to the diverse needs of architects worldwide. These finishes serve as excellent substitutes for expensive copper materials, providing an affordable yet luxurious alternative. As a viable alternative to bronze materials, our Antique Finish series provides a solution to procurement and other challenges associated with traditional bronze products.

Learn More

It is recommended primarily for internal use, where its unique aesthetic can enhance any space. Please contact us for further information and to discuss specific color requirements, as our antique series offers a wide range of customizable options. -

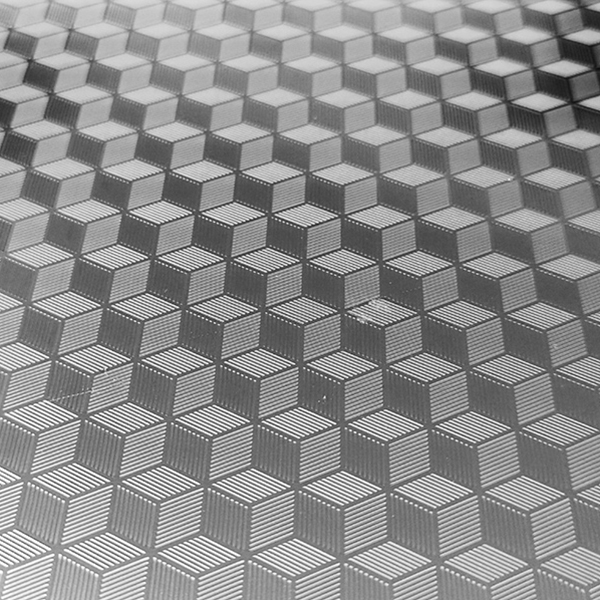

Embossed Finish

An embossed finish is a decorative treatment applied to stainless steel sheets to give them a textured or patterned surface. Embossed finishes can come in various patterns and designs, including geometric shapes, floral motifs, or custom designs. The embossing is typically achieved through mechanical processes, such as roller embossing or pressing the sheet between patterned rollers. Laser technology also be used to create precise and intricate some embossed patterns.

Learn More -

Bead Blasted Finish

Bead blasting is a surface treatment technique used to create a textured or matte finish on stainless steel. In this process, small glass beads or ceramic beads are propelled at high speed onto the stainless steel surface, which results in a uniform and consistent matte appearance.

Learn More

It's worth noting that we support customised finish roughness requirements and can guarantee flatness on both sides of the bead-blast.

By adjusting the base material from 2B, BA or one that has been mirror polished, the sheen of the finish can be adjusted as per the project requirements. -

Vibration Finish

It is a popular surface treatment that creates a distinctive, uniform pattern on the surface of the stainless steel. The vibration finish is achieved by mechanically brushing the stainless steel surface with abrasive materials, typically using a specialized machine or equipment. The brushing action creates a consistent pattern of fine lines or grains that run in multiple directions, giving it a non-directional or random appearance. This finish is often preferred for its aesthetic appeal, as it can add a unique texture and visual interest to stainless steel surfaces.

Learn More

By adjusting the base material from 2B, BA or one that has been mirror polished, the sheen of the finish can be adjusted as per the project requirements. -

Mirror Finish

A radiant and polished finish that enhances the brilliance of stainless steel. This exquisite finish effortlessly reflects its surroundings, creating an expansive ambiance when applied to both interior and exterior. Mirror finish sheets also serve as captivating accent pieces: strategically positioning the mirrored surface can beautifully showcase scenery, artworks, and even individuals. The stunning luminosity and sheen of the mirror finish make it a popular choice for embellishing fittings, frames, and ornaments, bestowing an air of opulence upon both building exteriors and interiors. Furthermore, its allure extends to interior decor, adding a touch of luxury to any space.

Learn More -

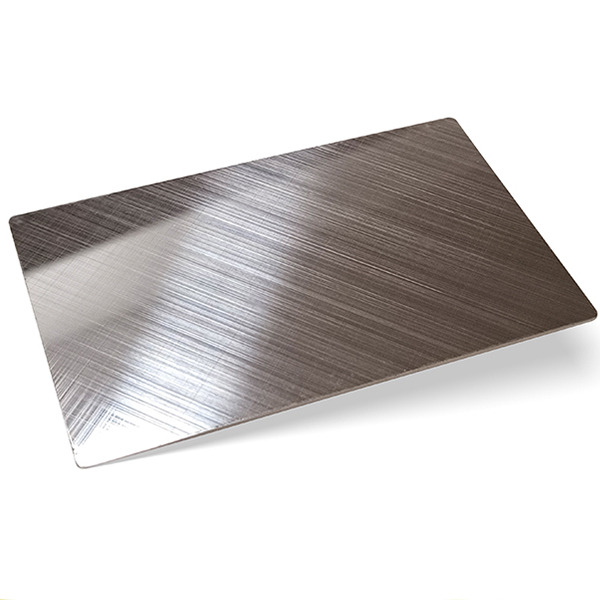

Brushed Finish

A brushed finish, also known as a satin finish, is a type of surface treatment applied to stainless steel to create a textured appearance. It is achieved by mechanically brushing the stainless steel surface with fine abrasive materials in a consistent linear pattern.

Learn More

There are different variations of brushed finishes, including: No. 4 Finish/ Hairline Finish/ Cross Hairline Finish/ Satin Finish -

PVD Color Coating

PVD stands for Physical Vapor Deposition, which is a surface coating process used to apply a thin layer of material onto a substrate, such as stainless steel. When applied to metal finishes, this technique creates a thin, adhesive film that enhances the color, appearance, durability, and properties of the it.

Learn More

X-Metal boasts several established production lines dedicated to PVD coating. Our team of specialists possesses the expertise to tailor the coating finish to meet the specific preferences and requirements of our clients. This includes, but is not limited to, customization of colors, degree of durability, and other desired characteristics.

We're here to assist you!

CONTACT

Contact Our Experts

EN

EN