Stainless steel bead blasting, a surface treatment technique used extensively across various industries, plays a pivotal role in sectors ranging from automotive to construction, and from medical equipment manufacturing to aerospace. This process offers a plethora of advantages, such as enhancing the aesthetic appeal of stainless steel parts, prolonging their lifespan, and boosting their resistance to corrosion. But what exactly is stainless steel bead blasting, and why is it so beneficial? This comprehensive guide will delve into the intricate details, offering you a profound understanding of this indispensable process.

Stainless steel bead blasting is a process that involves propelling small bits of material, known as blasting media, at high speeds towards a stainless steel surface. This process is used to remove surface contaminants, provide a uniform matte finish, and prepare the surface for subsequent processes like painting or coating. The result is a clean, smooth, and aesthetically pleasing surface that is free from rust, scale, and other forms of contamination.

The process is widely used in various industries due to its versatility and effectiveness. Whether it's automotive parts, kitchen appliances, or architectural structures, stainless steel bead blasting can significantly enhance the appearance and functionality of stainless steel components. It's a process that has revolutionized the way we treat and handle stainless steel, making it an integral part of modern manufacturing and maintenance operations.

The process of stainless steel bead blasting begins with the selection of appropriate blasting media. The choice of media depends on the desired finish and the nature of the workpiece. Commonly used media for stainless steel bead blasting include glass beads, aluminum oxide, and silicon carbide.

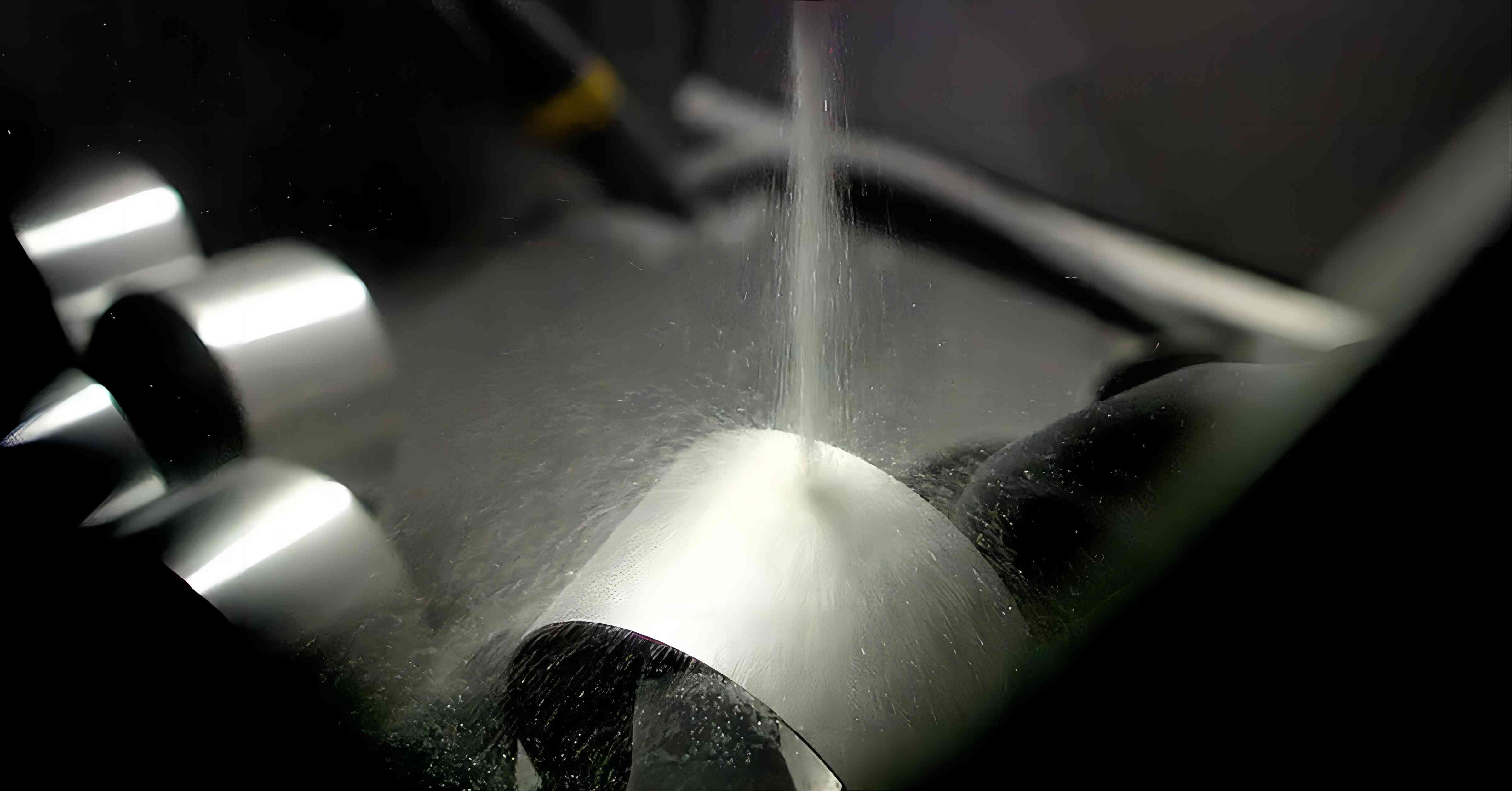

The blasting process is carried out in a blasting cabinet, where the workpiece is placed. The blasting media is then propelled at high speed towards the workpiece using a blasting gun. The impact of the media on the stainless steel surface removes contaminants and provides a uniform finish.

It's important to note that the process requires skilled operators, as the quality of the finish depends on factors such as the speed, angle, and distance of blasting. Moreover, proper safety measures should be in place to protect the operators from potential hazards such as flying debris and loud noise. Operators should wear appropriate personal protective equipment, including safety glasses, ear protection, and dust masks.

The process also requires careful control of other parameters, such as the pressure of the blasting media and the size of the media particles. These factors can significantly affect the quality of the finish and the efficiency of the process. For example, using a higher pressure can increase the speed of the process, but it can also cause more wear and tear on the blasting equipment and potentially damage the surface of the workpiece.

For projects that require specific surface roughness after bead blasting, we offer customized treatments. We use specialized instruments to measure and ensure the desired surface roughness, providing you with the exact finish you need. However, it's important to note that such customized treatments may incur higher processing costs due to the additional steps and precision required.

In addition to this, we also offer double-sided sand blasting for sheet materials. This is a specialized process that many suppliers struggle with due to the challenges in maintaining flatness. However, with our advanced techniques and experienced team, we can effectively handle double-sided sand blasting and ensure excellent flatness, meeting and exceeding your project requirements.

The choice of material for stainless steel sand blasting depends on the specific requirements of the project. For instance, if the goal is to achieve a smooth, matte finish, glass beads are an excellent choice. They are less aggressive than other media and provide a uniform, satin-like finish.

On the other hand, if the objective is to remove heavy rust or scale, a more aggressive media like aluminum oxide may be more suitable. It's harder and sharper than glass beads, making it effective for heavy-duty blasting tasks.

The choice of material also depends on the nature of the stainless steel part. For example, if the part has a complex shape or intricate details, a softer media like plastic beads may be more suitable to avoid damaging the part. On the other hand, for large, flat surfaces, a harder media like steel grit can be used for faster and more efficient removal of contaminants.

The choice of material also affects the cost of the process. Some materials, like aluminum oxide, are more expensive than others, like glass beads. However, the higher cost of some materials can be offset by their higher efficiency and the quality of the finish they provide.

As mentioned earlier, the choice of blasting media plays a crucial role in the bead blasting process. Here's a closer look at some of the most commonly used media:

Glass Beads: Glass beads are ideal for applications that require a clean, bright, satin finish. They are also environmentally friendly, as they can be recycled and do not produce hazardous dust. Glass beads are available in various sizes, allowing for a range of finishes from coarse to smooth.

Aluminum Oxide: Known for its high cutting speed and recyclability, aluminum oxide is suitable for aggressive cleaning and surface preparation tasks. It's also harder than most other abrasive materials, making it an excellent choice for heavy-duty applications. Aluminum oxide is available in various grit sizes, allowing for a range of finishes from rough to smooth.

Silicon Carbide: This is one of the hardest blasting media available. It's ideal for fast stripping and surface preparation, and it can be used on hard metals like stainless steel. Silicon carbide is also available in various grit sizes, allowing for a range of finishes from coarse to smooth.

Each of these media has its own advantages and disadvantages, and the choice of media should be based on the specific requirements of the project. It's also important to consider the environmental impact of the media, as some media can be recycled and reused, reducing waste and environmental impact.

Stainless steel bead blasting offers numerous benefits. Firstly, it improves the aesthetic appeal of stainless steel parts by providing a uniform, matte finish. This process is also effective in removing surface contaminants like rust and scale, thereby enhancing the lifespan and performance of the parts.

Moreover, bead blasting prepares the surface for subsequent processes like painting or coating, ensuring better adhesion and longer-lasting results. It's also a cost-effective method, as the blasting media can be recycled and reused.

In addition to these benefits, stainless steel bead blasting also improves the corrosion resistance of the parts. By removing surface contaminants and providing a uniform surface finish, bead blasting reduces the risk of corrosion, enhancing the longevity and reliability of the parts.

In conclusion, stainless steel bead blasting is a versatile and efficient surface treatment technique. Whether you're looking to improve the aesthetic appeal of your parts, increase their lifespan, or prepare them for subsequent processes, bead blasting can be an excellent choice. However, it's crucial to choose the right blasting media and follow proper safety measures to ensure optimal results and safe operations.

With the right knowledge and skills, stainless steel bead blasting can significantly enhance the quality and performance of your stainless steel parts. So, whether you're a manufacturer, a service provider, or a DIY enthusiast, understanding the process of stainless steel bead blasting can be highly beneficial.

By continuing to use the site you agree to our privacy policy Terms and Conditions.