Have you ever wondered, "Is stainless steel magnetic?" If you have, you're not alone. This question has sparked numerous debates and discussions. Some argue that stainless steel is entirely non-magnetic, while others insist that it must be magnetic due to its iron content. The truth, as is often the case, lies somewhere in between.

Stainless steel is a versatile metal alloy, composed of iron, chromium, silicon, carbon, nitrogen, and manganese. It's renowned for its resistance to tarnishing and exceptional corrosion resistance, making it a preferred choice for various applications. For an alloy to be classified as 'stainless,' it must contain at least 10.5% chromium and no more than 1.2% carbon.

The magnetic properties of stainless steel are primarily determined by its chemical composition and crystal structure. When alloyed, ferrite and iron crystal structures impart magnetic properties to stainless steel. However, high levels of austenite can counterbalance the ferrites, making these stainless steel alloys non-magnetic.

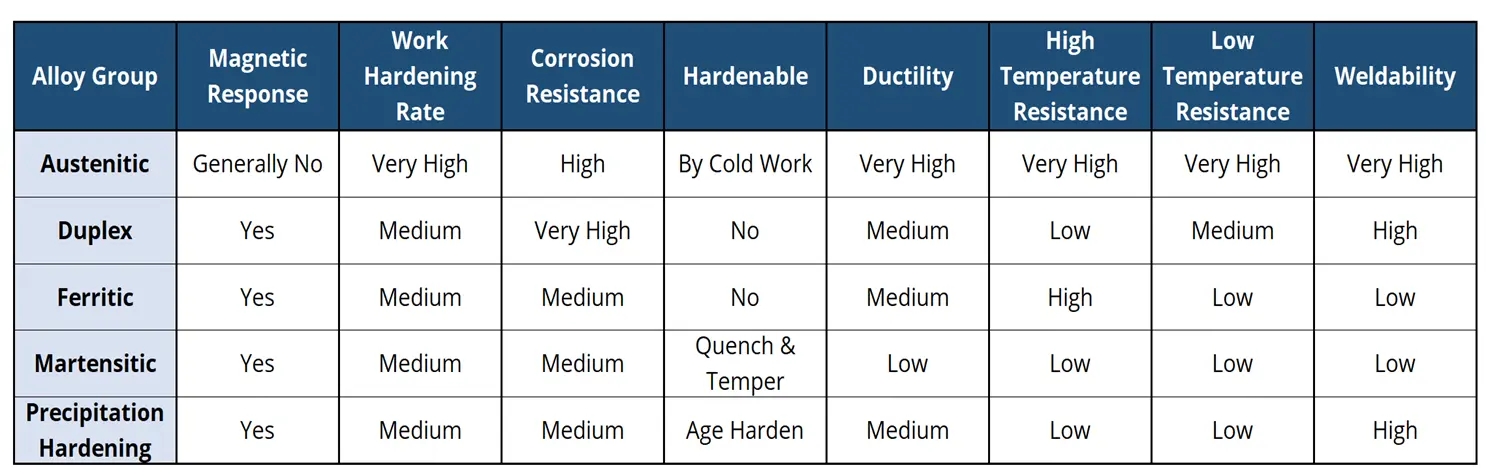

Stainless steel is not a monolithic entity but a family of alloys, each with unique properties. Based on their internal composition, we can categorize stainless steels into five distinct groups:

Austenitic stainless steels

Ferritic stainless steels

Martensitic stainless steels

Duplex stainless steels

Precipitation-hardened steels

Austenitic Stainless Steels

Austenitic stainless steels, including popular grades like 304 and 316, are generally non-magnetic due to the dominant presence of austenite. Despite having high iron content, the austenite structure renders them non-ferromagnetic. However, with special thermal treatment or work hardening, these alloys can become partially magnetic.

Ferritic Stainless Steels

Ferritic stainless steels, such as the 400 series, are magnetic due to their large ferrite composition. Ferrite, a compound of iron and other elements, combined with a ferritic crystal structure, gives these stainless steels their magnetic properties.

Duplex Stainless Steels

Duplex stainless steels offer a balance of corrosion resistance, easy fabrication, and cost savings due to the absence of nickel. The mixture of austenitic and ferritic crystals within these steels contributes to their magnetic properties.

Martensitic Stainless Steels

Martensitic stainless steels, including common grades such as 410, 420, and 440, are inherently magnetic. The unique crystal structure of these steels can be ferromagnetic if iron is present.

Misconceptions About Stainless Steel and Magnetism

It's a common misconception that the magnetism of a stainless steel sheet can be used to determine if the material is indeed stainless steel. Many people believe that if a magnet sticks to a stainless steel sheet, it's not stainless steel. However, as we've discussed, the magnetic properties of stainless steel are complex and cannot be determined by a simple magnet test.

Stainless Steel Types Chart

So, how can we accurately determine the composition of a stainless steel material? The most reliable method is through a detailed chemical analysis. This process involves analyzing the material to identify its elemental composition. By doing so, we can accurately determine the type of stainless steel and its properties.

There are several ways to conduct a detailed chemical analysis of stainless steel:

Spectrometer: A spectrometer can be used to analyze the material and identify its elemental composition. This device works by measuring the intensity of the light spectrum, which can be used to determine the elements present in the material.

Stainless Steel Composition Testing by Spectrometer

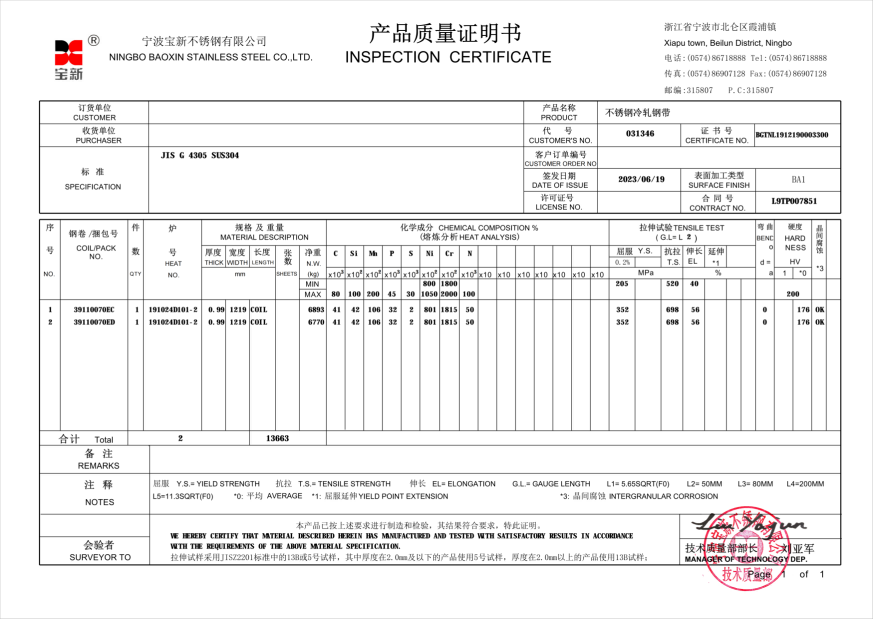

Mill Test Certificate: A Mill Test Certificate (MTC) is a quality assurance document in the steelmaking industry that certifies a material's chemical and physical properties and states a product made of metal complies with international standards organizations' specific standards.

304 DQ BA MTC

Professional Testing Agencies: You can also send the material to a professional testing agency. These agencies have the necessary equipment and expertise to accurately determine the composition of stainless steel.

Magnetism in stainless steel can significantly impact the material's performance, depending on its application. For instance, in manufacturing processes like welding and fabrication operations, magnetic materials can interfere with the welding spark, leading to poor welds.

In conclusion, the magnetic properties of stainless steel are complex and depend on the specific alloy and its composition. By understanding these properties, we can make more informed decisions when selecting materials for specific applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.