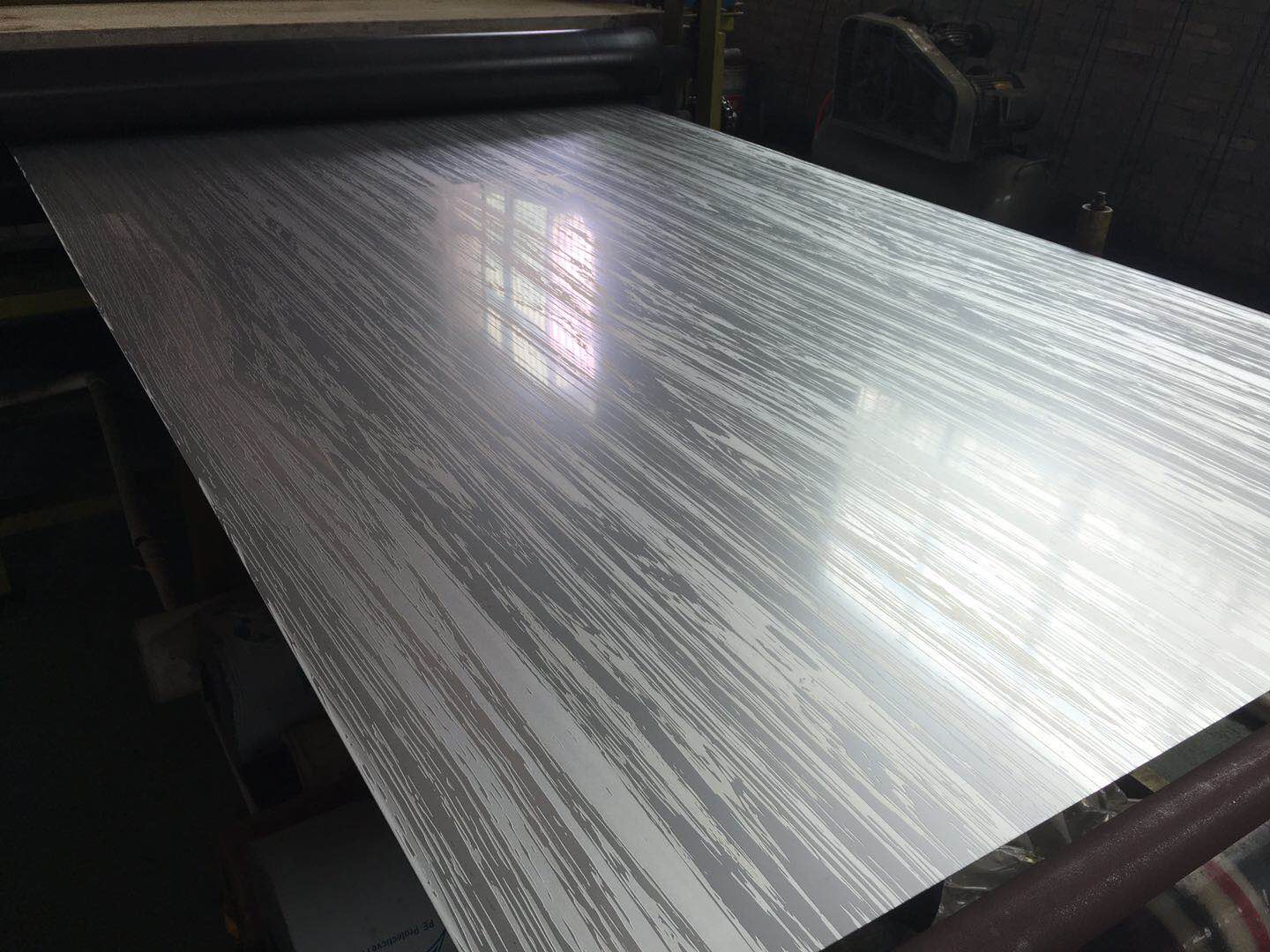

Etching is a vital process extensively used in the manufacturing of various metal materials, including stainless steel, copper, and aluminum. It serves as a robust protective measure against acid and alkali corrosion, making it an essential process in the production of stainless steel etched sheets and elevator sheets. Etching inks are available in different colors, with blue and black being the most prevalent, and a small portion being transparent.

Etching is primarily categorized into acid etching and alkali etching. Some manufacturers, with a keen eye on environmental sustainability, also utilize electrolytic etching. However, the market for inks resistant to electrolytic etching is currently sparse. If high electrolytic requirements are necessary, it is advisable to use a curing agent to prevent the electrolytic ions from penetrating the ink.

Protective decorative etching inks are further classified into silk-screen etching inks and photosensitive etching inks. But what sets these two types of inks apart?

Silk-screen etching ink is directly applied to the metal surface using a silk-screen, protecting the parts that do not need to be etched. After drying, an acid etching solution is used for corrosion, commonly using ferric chloride for etching. This method is suitable for mass production of etched decorative sheets. One silk-screen can produce many etched products with the same pattern. It is also used in the production of single-sided circuit boards.

The advantage of silk-screen etching ink is its simplicity. It eliminates the need for exposure and development processes, simplifying the etching process. As the ink does not contain photosensitizers, it does not react with light, allowing for non-light-avoiding inking. However, its adhesion is slightly inferior to photosensitive etching ink, and it can be removed more quickly. The downside is that it is not suitable for fine etching or for hardware nameplates with many styles but small quantities, as the cost of making various pattern screens is high.

Silk-screen etching inks are generally black. Due to the use of screen printing, the ink requires a higher viscosity, so it should not be diluted too much when diluting. It is generally recommended to add 1-5%. It can be diluted with anti-white water or tian na water. The recommended mesh size is between 100-300 meshes.

Photosensitive etching ink, also known as photosensitive blue ink or etching blue ink, is a blue anti-corrosion ink. The color blue is used because it has a lower exposure energy requirement. After etching, the ink needs to be removed, so the end user of etching doesn't have specific color requirements for the ink.

Photosensitive etching ink can be applied in various ways, including silk-screening, roll coating, or spray coating. Depending on the method of application, the proportion of diluent added will vary. Generally, silk-screening adds 1-5%, roll coating adds 10-20%, and spray coating adds 30-45% diluent.

The best diluent is anti-white water, also known as butyl cellosolve, which is commonly used. However, when used to dilute photosensitive blue oil, it can easily cause bubbles. It is recommended to stir evenly and let the ink stand for about 20 minutes. If tian na water is used to dilute the ink, the diluted ink will dry faster, but the smell will be stronger.

Photosensitive etching ink can dry naturally, but it should be stored in a light-avoiding place to prevent the ink from being exposed to light before exposure. This is because photosensitive etching ink contains a photosensitizer, which reacts with ultraviolet light. If the area that needs to be developed reacts with light, it will not be developed.

The development of photosensitive ink uses a 1% sodium carbonate solution, and the development time is about 1-3 minutes. After developing the pattern, rinse it clean with water, and then you can start etching. Etching uses a ferric chloride solution, and a concentration of 40-60% is appropriate.

After etching, the ink needs to be removed. It is generally recommended to use a 5% sodium hydroxide aqueous solution at a temperature of 50-80 degrees Celsius.

In conclusion, whether it's photosensitive etching ink or silk-screen thermosetting etching ink, their function is to print and adhere to the metal surface, providing protection. The areas with ink can prevent being corroded by the acid etching solution. Photosensitive etching ink requires a higher resolution because it is mainly used in various high-precision projects, such as the production of stainless steel etched sheets and elevator sheets.

Are you interested in learning more about the etching process or need assistance with your etching project? Our team of experts is ready to help. We have extensive experience in the field and can provide guidance on the best etching methods for your specific needs. Whether you're working with stainless steel etched sheets, elevator sheets, or other materials, we've got you covered. Contact us today to get started!

By continuing to use the site you agree to our privacy policy Terms and Conditions.