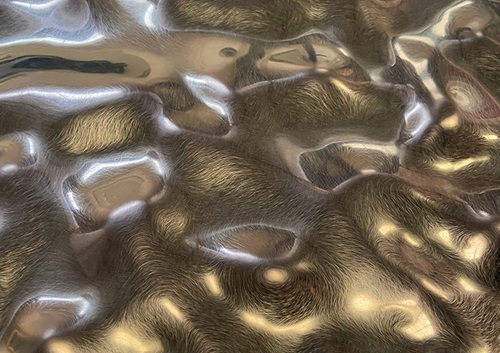

Water ripple sheet metal, with its distinctive pattern resembling natural water ripples, has become a focal point in various industries. This comprehensive article delves deeply into the intricate process of crafting water ripple sheet metal while thoroughly exploring its diverse applications. From the meticulous manufacturing process to real-world applications, we will unravel the technical aspects while ensuring the content is not only accessible but also rich in professional knowledge, presenting an article that mirrors a human touch in its writing style.

The production of water ripple sheet metal involves a meticulous process that seamlessly combines precision and creativity. This intricate journey begins with the careful selection and preparation of materials. Metals such as stainless steel, aluminum, and copper are chosen for their unique properties. These materials undergo a series of rigorous processes, including cleaning, shaping, and treatment, ensuring they meet the desired specifications.

The heart of the crafting process lies in the techniques employed to achieve the mesmerizing water ripple pattern. Complex and controlled processes such as stamping, rolling, or pressing are applied to induce the characteristic ripples. The precision of these techniques is paramount, as it directly influences the quality of the final product. This amalgamation of mechanical prowess and artistic finesse defines the craftsmanship involved in the manufacturing process.

The versatility of water ripple sheet metal extends across a spectrum of industries, each harnessing its unique aesthetic and functional properties for specific applications.

In architectural contexts, water ripple sheet metal emerges as a symbol of decorative brilliance. Architects and designers leverage its captivating pattern to elevate the visual appeal of buildings. Whether adorning entire façades or incorporated into interior design elements, the material introduces a nuanced blend of modernity and elegance. The reflective nature of the metal adds a dynamic dimension to architectural spaces, capturing and playing with ambient light to create visually stunning environments.

Within the realm of furniture design, water ripple sheet metal showcases its malleability and visual allure. Crafted into masterpieces such as tables, cabinets, and other furnishings, the material becomes more than a functional element; it transforms into an artistic expression. The undulating ripples on the surface of furniture pieces contribute to a sense of movement and flow, making them focal points in interior spaces. This intersection of form and function establishes water ripple sheet metal as a preferred choice for those seeking to infuse their living spaces with both style and substance.

Moving beyond aesthetics, water ripple sheet metal finds substantial utility in various industrial and technological applications. Its durability, corrosion resistance, and formability make it an ideal candidate for manufacturing components in high-tech sectors. In the electronics industry, for instance, the material's ability to withstand harsh environmental conditions ensures the longevity and reliability of electronic devices. Similarly, in the automotive sector, its lightweight nature coupled with robustness makes it suitable for manufacturing components that contribute to both fuel efficiency and safety.

Beyond conventional applications, water ripple sheet metal is increasingly finding its way into artistic endeavors. Sculptors and artists incorporate the material into their creations, leveraging its unique visual texture to evoke emotions and create engaging visual experiences. The interplay of light and shadow on the rippled surface adds a dynamic quality to art installations, making them intriguing and thought-provoking.

In essence, the diverse applications of water ripple sheet metal underscore its adaptability and appeal across industries. Whether enhancing the architectural landscape, contributing to innovative furniture designs, powering technological advancements, or serving as a medium for artistic expression, this material continues to redefine the boundaries of its utility, solidifying its place as a versatile and valued component in the modern industrial and creative landscape.If you want to know more, please contact us.

By continuing to use the site you agree to our privacy policy Terms and Conditions.